-

tel:

+86 16651737187 -

email:

shanyf@chinasti.com

THV Test System Technical Parameters (Chamber)

THV Test System Technical Parameters (Chamber)

STI provides the combined environmental test systems with integrated design and control, and we believe it will bring a better experience to the user.

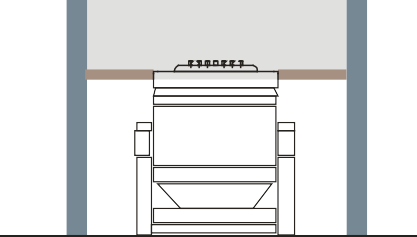

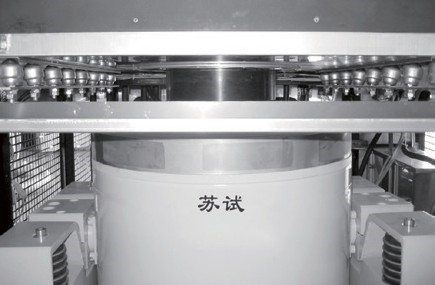

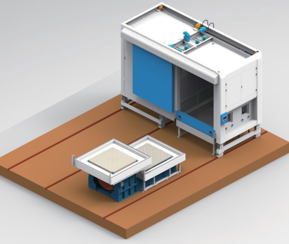

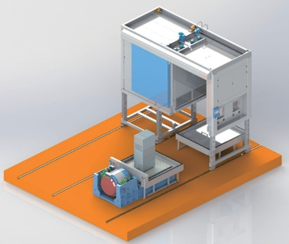

THV Test System 1

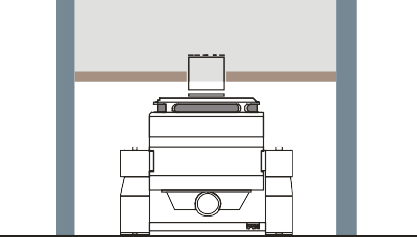

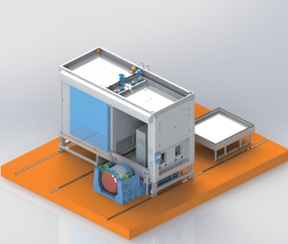

THV Test System 2

The THV Test system developed by STI has the following advantages in structure:

- Systematic: Combine vibration system and climatic environment system

- Operability: greatly reduce the intensity of manpower operation, as far as possible to reduce human intervention.

- Aesthetics: The color matching of vibration system and climate environment system is harmonized.

- Safety: Due to the great reduction of manpower operation, safety has been well guaranteed.

Features

Comprehensive environment integrated CEC 3000 controller (test setting and display are in the same software and the same interface)

Integration design of shaker with temperature chamber

Setting and display temperature vibration working conditions in the one interface

Precise timeline consistent

Multiple interface connections between shaker and temperature chamber

Variety of moving methods, according to the site decided to move the shaker or temperature chamber

Standard 8-channel digital I / O ports

Optional

Dry windswept function Deionized water device

Lowe humidity and temperature function

Test Standard

GB/T2423

GJB150

Connection Methods between Vibrator and Environmental Test System

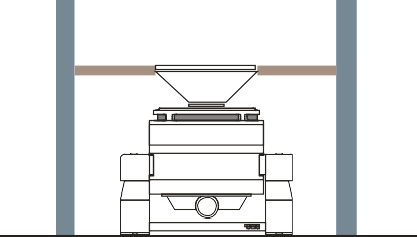

Shaker connects the environmental test chamber directly

Shaker connects the environmental test chamber through a connector

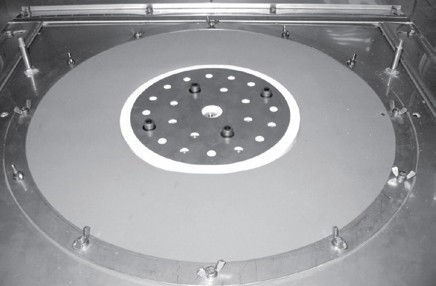

Shaker connects the environmental test chamber through the head expander

Station switching process:

The vertical base plate is a movable plate, which can be placed on the vertical table bracket or a separate base plate bracket. The horizontal base plate is a fixed base plate fixed to the horizontal base of the shaker. The test chamber has the function of lifting and horizontal movement, and the test chamber has suspension points that can be hung on the bottom plate and locked.

HC-3000 & CEC-3000 Controller

HC-3000 Controller

HC-3000 controller is developed specially for RS Highly Accelerated Life Testing and Highly Accelerated Stress Screening.

HC-3000 controller control the hitting intensity of pneumatic hammers, inlet volume of liquid nitrogen and electric heating elements on/off, the measurement object is temperature and broadband random spectrum. HC-3000 controller integrates the functions of control, signal acquisition and signal analysis.

HC-3000

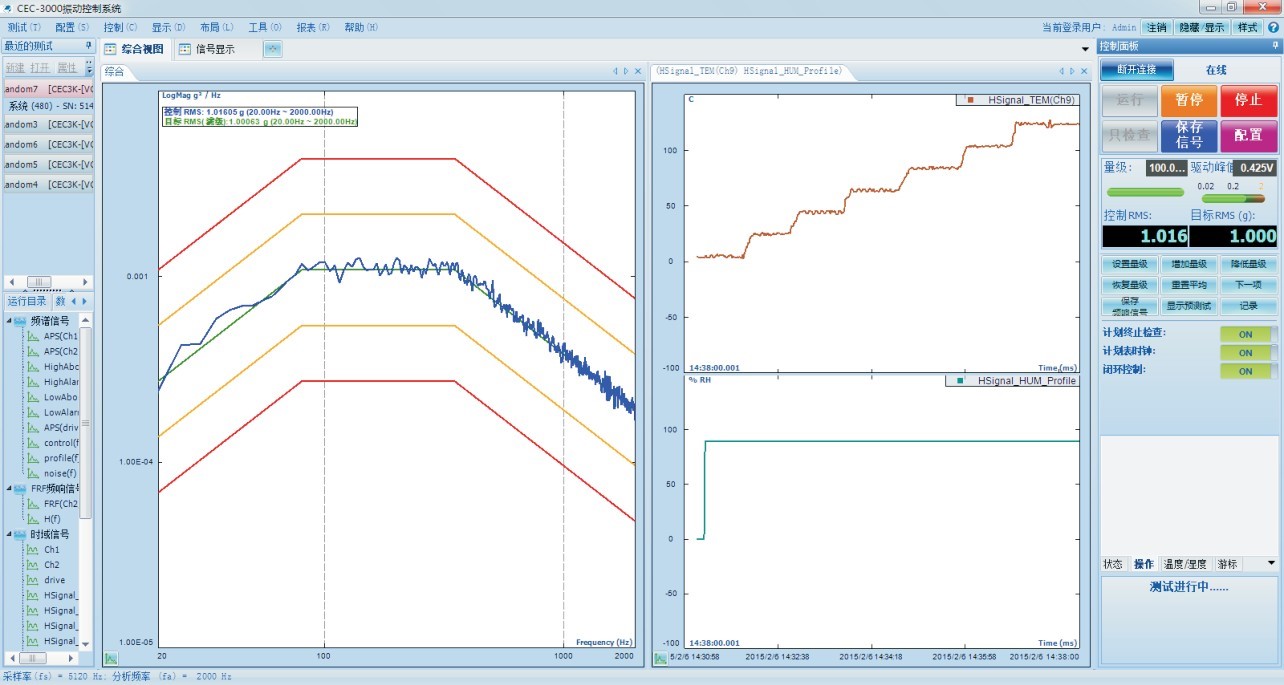

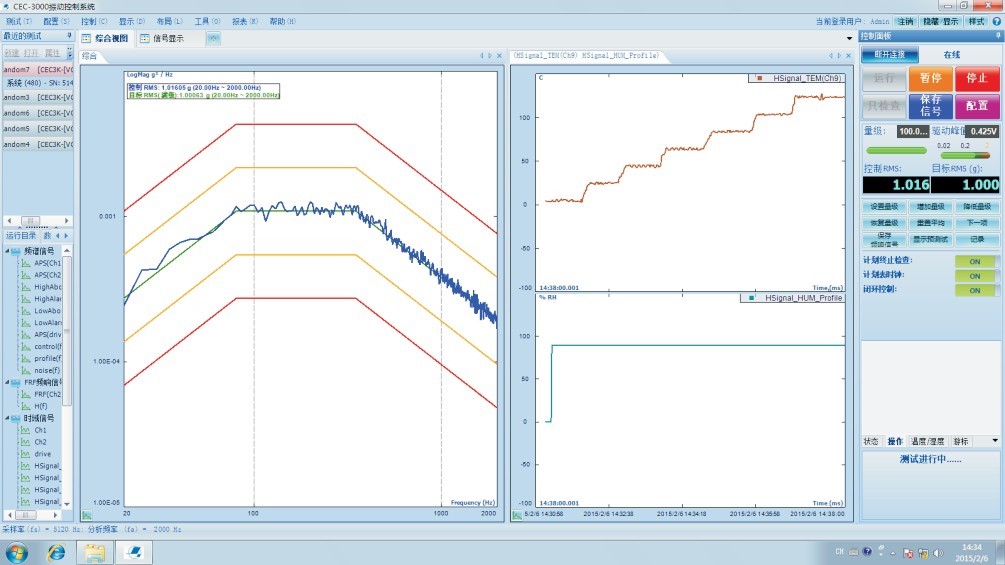

CEC-3000 Controller

CEC-3000 controller is developed for combined environmental test systems, the control objects are ED shaker, refrigeration units, electric heating elements, humidification components. And CEC-3000 controller integrates the functions of control, signal acquisition and signal analysis.

The control and measuring contents of CEC-3000 controller is similar RC-3000 controller. HC-3000 controller and CEC-3000 has similar hardware configuration.

CEC-3000

Hardware

Vibration Input Channel Number: 4 (can be extended)

Connection Method: BNC

Coupling Mode: AC, DC, IEPE, Charge

Input Dynamic Range: 100dB

Sampling Frequency: Max. 102.4 kHz

Temperature Input Channel Number: 4 (can be extended)

Sensor Type: T type thermocouple or PT100

Power Supply Method: external DC power supply

Communication: Network

Software

Features

- Simple network connection

Ethernet connection allows HC-3000 and CEC-3000 can be installed in places away from the computer host. The distribution structure can greatly reduce system noise and electromagnetic interference. A PC can control multiple HC-3000 and CEC- 3000simultaneously by Ethernet. Because the control flow and data reading process is handled inside of the control machine, the Ethernet connection will not reduce the reliability of the system. Via a wireless router, PC or even can connect the WI-FI to control the Controller.

- Excellent control design

Using advanced control algorithms and a simplified DSP architecture, the feedback time of the temperature and humidity time is reduced. Use the optimized adaptive PID control algorithm to meet the needs of different temperature curve. HC-3000 and CEC- 3000 also provides fast response to security protection.

- Integrated Dynamic analysis

HC-3000 and CEC-3000 integrates a large number of general-purpose signal analysis methods, include a time-domain signal recording, transient signal interception, FFT, auto power spectrum, transfer function analysis.

- Flexible hardware combinations

It can be arbitrarily superimposed into the multi-channel control system.

- HC-3000 and CEC-3000 can be connected to two temperatures sensors, to meet a wider temperature range and accuracy of measurements.

- Expandable external relay control and can write the test procedure

| THV Test System Technical Parameters (Chamber) | |||||||||||||

| Temperature Fluctuations | ℃ | ±0.5℃ | |||||||||||

| Temperature Deviation | ℃ | ±2℃ | |||||||||||

| Temperature Uniformity | ℃ | ≤2℃ | |||||||||||

| Humidity Range | %RH | 20~98 | |||||||||||

| Humidity Deviation | %RH | ≤75%RH: ≤±5%; >75%RH: ≤+2-3% | |||||||||||

| Dew Point Temperature | ℃ | +4~89.5 | |||||||||||

| Power Supply | 3/N/PE AC,380V±10%,50Hz | ||||||||||||

| Chamber model/volume | L | THV-600 | |||||||||||

| Test Area Dimensions | mm | 800W×800D×950H | |||||||||||

| Load | 25kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+180 | -40~+180 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85℃ | -55~+85℃ | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 9 | 12 | 19 | 25 | 9 | 17 | 23 | 36 | 7 | 10.5 | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 2.6 \N | 3.4 \N | 6.2 \N | 10.6 | 2.1 \N | 5.5 \N | 9.7 | 14 | 2.3 | 5.8 | \ | \ |

| Chamber model/volume | L | THV-1200 | |||||||||||

| Test Area Dimensions | mm | 1100W×1100D×1000H | |||||||||||

| Load | 50kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+180 | -40~+180 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85℃ | -55~+85℃ | ||||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 9 | 19 | 25 | 39 | 10 | 21 | 36 | 43 | 7.9 | 13.9 | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 2.6 \N | 6.2 \N | 10.6 | 16.1 | 2.9 \N | 6.8 \N | 14 | 16.1 | 2.8 | 7.4 | \ | \ |

| Chamber model/volume | L | THV-2200 | |||||||||||

| Test Area Dimensions | mm | 1400W×1400D×1100H | |||||||||||

| Load | 100kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+180 | -40~+180 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85℃ | -55~+85℃ | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 12 | 23 | 39 | 56 | 17 | 28 | 52 | 75 | 10.5 | 16.6 | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 3.4 \N | 7.7 \N | 16.1 | 20.9 | 5.5 \N | 12 | 19.8 | 27.3 | 5.8 | 8.4 | \ | \ |

| Chamber model/volume | L | THV-3300 | |||||||||||

| Test Area Dimensions | mm | 1500W×1500D×1500H | |||||||||||

| Load | 150kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+150 | -40~+150 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85℃ | -55~+85℃ | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 19 | 30 | 46 | 67 | 21 | 36 | 63 | 87 | 13.9 | 20 | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 6.2 \N | 12.4 | 18.5 | 26.5 | 6.8 \N | 14 | 23 | 30.7 | 6.4 | 10 | \ | \ |

| Chamber model/volume | L | THV-4800 | |||||||||||

| Test Area Dimensions | mm | 1800W×1800D×1500H | |||||||||||

| Load | 150kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+150 | -40~+150 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85℃ | -55~+85℃ | ||||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 23 | 39 | 81 | 93 | 23 | 43 | 87 | 126 | 13.9 | 24.6 | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 7.7/N | 16.1 | 29.5 | 34 | 9.7 | 16.1 | 30.7 | 46 | 6.4 | 11.7 | \ | \ |

| Chamber model/volume | L | THV-5800 | |||||||||||

| Test Area Dimensions | mm | 1800W×1800D×1800H | |||||||||||

| Load | 200kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+150 | -40~+150 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85 | -55~+85 | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 10 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 25 | 46 | 81 | 134 | 28 | 52 | 87 | 150 | 17.2 | 30 | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 10.6 | 18.5 | 29.5 | 53 | 12 | 19.8 | 30.7 | 54.6 | 7.4 | 13.6 | \ | \ |

| Chamber model/volume | L | THV-8000 | |||||||||||

| Test Area Dimensions | mm | 2000W×2000D×2000H | |||||||||||

| Load | 200kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+150 | -40~+150 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85 | -55~+85 | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 10 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 25 | 46 | 93 | 162 | 28 | 63 | 126 | 174 | 17.2 | \ | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 10.6 | 18.5 | 34 | 59 | 12 | 23 | 46 | 61.4 | 7.4 | \ | \ | \ |

| Chamber model/volume | m³ | THV-10 | |||||||||||

| Test Area Dimensions | mm | 2300W×2300D×2000H | |||||||||||

| Load | 200kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+150 | -40~+150 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85 | -55~+85 | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 10 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 39 | 67 | 134 | 200 | 36 | 75 | 150 | \ | 20 | \ | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 16.1 | 26.5 | 53 | 79.5 | 14 | 27.3 | 54.6 | \ | 7.9 | \ | \ | \ |

| Chamber model/volume | m³ | THV-12 | |||||||||||

| Test Area Dimensions | mm | 2200W×2200D×2600H/2500W×2500D×2000H | |||||||||||

| Load | 200kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+150 | -40~+150 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85 | -55~+85 | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 10 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 39 | 67 | 134 | 200 | 36 | 75 | 150 | \ | 20 | \ | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 16.1 | 26.5 | 53 | 79.5 | 14 | 27.3 | 54.6 | \ | 7.9 | \ | \ | \ |

| Chamber model/volume | m³ | THV-18 | |||||||||||

| Test Area Dimensions | mm | 3000W×3000D×2000H | |||||||||||

| Load | 250kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+150 | -40~+150 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85 | -55~+85 | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 10 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 46 | 81 | 162 | 186 | 52 | 104 | 174 | \ | 24.6 | \ | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 18.5 | 29.5 | 59 | 68 | 19.8 | 39.6 | 61.4 | \ | 9.7 | \ | \ | \ |

| Chamber model/volume | m³ | THV-24 | |||||||||||

| Test Area Dimensions | mm | 3000W×3000D×2600H | |||||||||||

| Load | 250kg Aluminum ingots | ||||||||||||

| Temperature Range | ℃ | -70~+150 | -40~+150 | ||||||||||

| Temperature Change Assessment Range | ℃ | -40~+85 | -55~+85 | \ | |||||||||

| Temperature Ramp Rate | ℃/min | 2 | 5 | 10 | 15 | 2 | 5 | 10 | 10 | 2 | 5 | 10 | 15 |

| Rated Power | kW | 46 | 81 | 162 | 243 | 63 | 104 | \ | \ | 34 | \ | \ | \ |

| Cooling Water Flow (+30℃) | t/h | 18.5 | 29.5 | 59 | 89 | 23 | 39.6 | \ | \ | 11.6 | \ | \ | \ |

Note:

1. Temperature change rate, range, humidity and other parameters can be customized according to needs

2. The volume and size of the chamber can be customized according to needs

3. The product manufacturing standard meets IEC 60068-3-5 and JJF 1101-2003

4. The temperature change rate is assessed in the range of ambient temperature 23±3°C

5. Cooling water flow with "/N" is optional air cooling (greatly affected by the environment, not recommended)

6. The rated power in the table is low temperature holding power, and the actual installed power is subject to the scheme

| THV 600 | THV 1200 | THV 2200 | THV 3300 | THV 4800 | THV 5800 | THV 8000 | THV 10 | THV 1(2 2222) | THV 1(2 2525) | THV 18 | THV 24 | |

| DC-1000/SV-0505 | ○ | ○ | ||||||||||

| DC-1000/SV-0606 | ○ | ● | ||||||||||

| DC-1000/SV-0808 | ● | |||||||||||

| DC-2200/SV-0505 | ○ | ○ | ||||||||||

| DC-2200/SV-0606 | ● | ● | ||||||||||

| DC-2200/SV-0808 | ● | |||||||||||

| DC-3200/ST -1010 | ● | ○ | ||||||||||

| DC-3200/ST -1212 | ○ | ● | ||||||||||

| DC-3200/SV-0505 | ● | ○ | ||||||||||

| DC-3200/SV-0606 | ● | ● | ||||||||||

| DC-3200/SV-0808 | ● | ● | ||||||||||

| DC-3200/SV-1010 | ● | ○ | ||||||||||

| DC-3200/SV-1212 | ○ | ● | ||||||||||

| DC-4000/ST -1010 | ● | ○ | ||||||||||

| DC-4000/ST -1212 | ○ | ● | ○ | |||||||||

| DC-4000/SV-0505 | ● | ○ | ||||||||||

| DC-4000/SV-0606 | ● | ● | ||||||||||

| DC-4000/SV-0808 | ● | ● | ||||||||||

| DC-4000/SV-1010 | ● | ○ | ||||||||||

| DC-4000/SV-1212 | ○ | ● | ○ | |||||||||

| DC-5000/ST -1010 | ● | ○ | ||||||||||

| DC-5000/ST -1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-5000/ST -1515 | ● | ● | ● | ● | ● | ○ | ||||||

| DC-5000/ST -2020 | ○ | |||||||||||

| DC-5000/SV-0505 | ○ | |||||||||||

| DC-5000/SV-0606 | ● | |||||||||||

| DC-5000/SV-0808 | ● | ○ | ||||||||||

| DC-5000/SV-1010 | ● | ○ | ||||||||||

| DC-5000/SV-1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-5000/SV-1515 | ● | ● | ● | ● | ● | ● | ||||||

| DC-6000/ST -1010 | ● | ○ | ||||||||||

| DC-6000/ST -1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-6000/ST -1515 | ● | ● | ● | ● | ● | ○ | ||||||

| DC-6000/ST -2020 | ○ | ○ | ||||||||||

| DC-6000/SV-0505 | ○ | |||||||||||

| DC-6000/SV-0606 | ○ | |||||||||||

| DC-6000/SV-0808 | ● | ○ | ||||||||||

| DC-6000/SV-1010 | ● | ○ | ||||||||||

| DC-6000/SV-1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-6000/SV-1515 | ● | ● | ● | ● | ● | ○ | ||||||

| DC-6500/ST -1010 | ● | ○ | ||||||||||

| DC-6500/ST -1212 | ○ | ● | ● | ● | ○ | |||||||

| DC-6500/ST -1515 | ● | ● | ● | ● | ● | ○ | ||||||

| DC-6500/ST -2020 | ○ | ○ | ||||||||||

| DC-6500/SV-0505 | ○ | |||||||||||

| DC-6500/SV-0606 | ○ | |||||||||||

| DC-6500/SV-0808 | ● | ○ | ||||||||||

| DC-6500/SV-1010 | ● | ○ | ||||||||||

| DC-6500/SV-1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-6500/SV-1515 | ● | ● | ● | ● | ● | ○ | ||||||

| DC-7500/ST -1010 | ● | ○ | ||||||||||

| DC-7500/ST -1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-7500/ST -1515 | ● | ● | ● | ● | ● | ○ | ||||||

| DC-7500/ST -2020 | ○ | ○ | ||||||||||

| DC-7500/SV-0505 | ○ | |||||||||||

| DC-7500/SV-0606 | ○ | |||||||||||

| DC-7500/SV-0808 | ● | ○ | ||||||||||

| DC-7500/SV-1010 | ● | ○ | ||||||||||

| DC-7500/SV-1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-7500/SV-1515 | ● | ● | ● | ● | ● | |||||||

| DC-12000/ST -1010 | ○ | ○ | ||||||||||

| DC-12000/ST -1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-12000/ST -1515 | ● | ● | ● | ● | ● | ● | ||||||

| DC-12000/ST -2020 | ○ | ● | ○ | ○ | ||||||||

| DC-12000/ST -2525 | ● | ○ | ||||||||||

| DC-12000/SV-0808 | ○ | |||||||||||

| DC-12000/SV-1010 | ○ | ○ | ||||||||||

| DC-12000/SV-1212 | ○ | ● | ○ | ○ | ○ | |||||||

| DC-12000/SV-1515 | ● | ● | ● | ● | ● | ○ | ||||||

| DC-20000/ST -1515 | ● | ○ | ||||||||||

| DC-20000/ST -2020 | ○ | ● | ● | ○ | ||||||||

| DC-20000/ST -2525 | ● | ● | ||||||||||

| DC-20000/SV-1515 | ● | ○ | ||||||||||

| DC-30000/ST -2020 | ○ | ○ | ||||||||||

| DC-30000/ST -2525 | ○ | ● |

Note:

● Preferred ○ Secondary