-

tel:

+86 16651737187 -

email:

shanyf@chinasti.com

HALT & HASS System

HALT & HASS System

Product Presentation

Highly accelerated life testing (HALT) is used to add more stress to the DUT, so that the product design flaws exposed time is much shorter than the time required for reliability under normal stress conditions. The purpose of the testing is to identify the operation and destruction limits of products during product development stage, to help customers improve design and build reliable products.

The main functions of highly accelerated life testing are shown as following.

- Quickly discover products' design weakness and destruction limit

- Analysis and improve products' designing limits

- Helping customers build reliable products

- Reduce time and cost of research and development

- Eliminate the design weakness before manufacturing

- Provide the basis for continuous evaluation of product improvement.

Highly accelerated stress screening (HASS) is different from highly accelerated life testing, is mainly used in the screening process after production. The stress of highly accelerated stress screening is smaller than highly accelerated life testing, but generally still higher than the designing stress limits. The purpose of highly accelerated stress screening is to find products' quality defects within a very short period of time. And the highly accelerated stress screening is based on the highly accelerated life testing.

The main functions of highly accelerated stress screening are shown as following.

- Optimize product design and production processes

- Improve products' quality and reliability

- Reduce maintenance cost

- Reduce products' early failure rate

HALT & HASS can provide the tests of vibration synchronization, temperature synchronization, vibration and temperature cycling and shock, integrated vibration and temperature and so on.

HALT & HASS have two working modes which are repetitive shock HALT & HASS and electro-dynamic HALT & HASS. And STI can provide both working modes test systems.

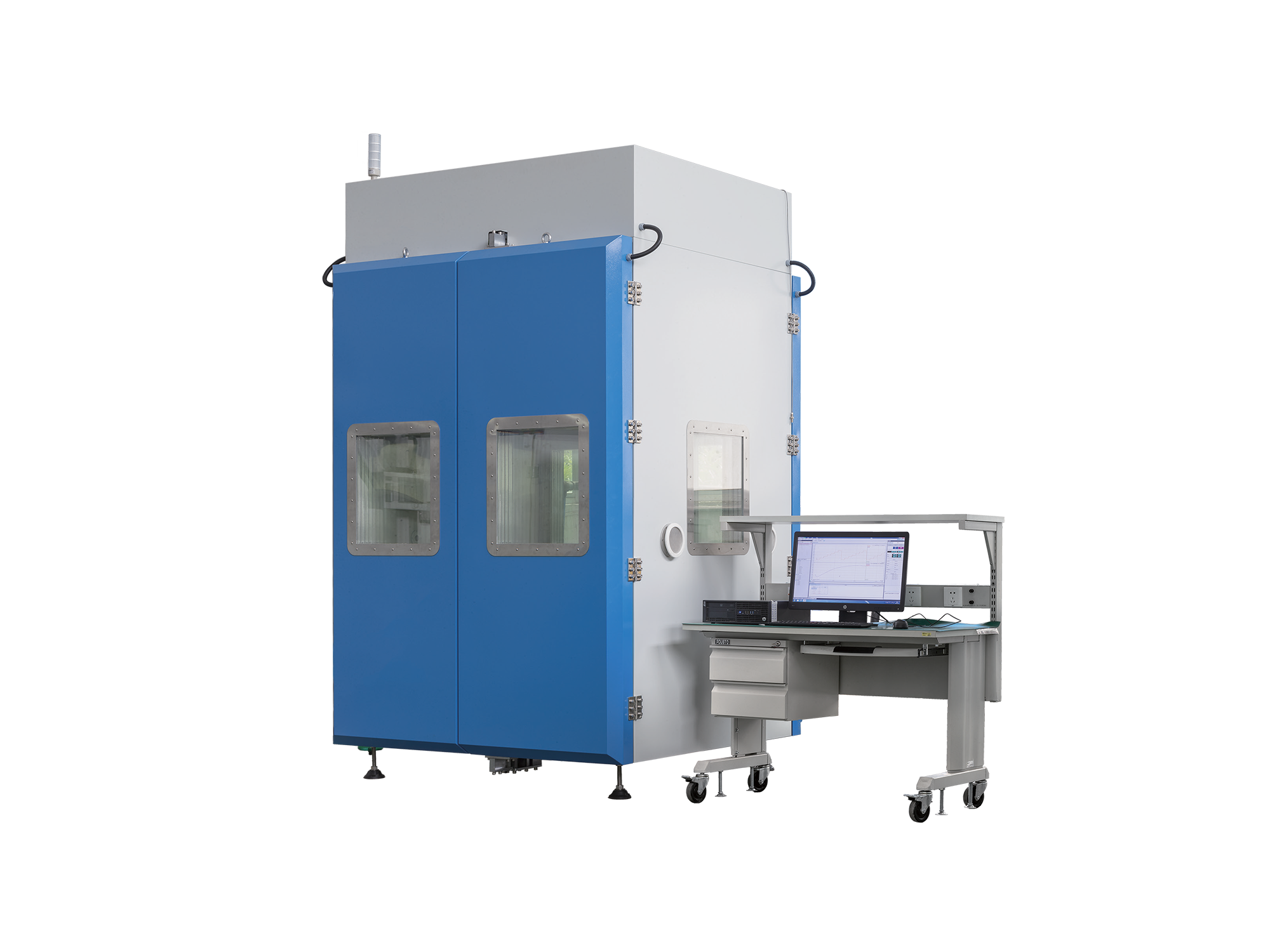

Repetitive Shock Highly Accelerated Life Testing and Highly Accelerated Stress Screening

RS HALT & HASS is made of pneumatic hammer vibration generator, rapid temperature chambers, integrated vibration and temperature controller. The pneumatic hammers hit the working table rapidly and transiently, the working table generates huge broad band spectrum vibration energy, by changing the hitting directions of pneumatic hammers generates three orthogonal axes vibration components, and produces the axis of rotational components by the spring support, to achieve the working mode of three- axis and six degrees of freedom. Changing the hitting frequency and intensity of pneumatic hammers, you can change the vibration frequency range and vibration levels.

RS HALT & HASS can generate the vibration energy from 10 Hz to 10 kHz.

Highly Accelerated Life Testing and Highly Accelerated Stress Screening

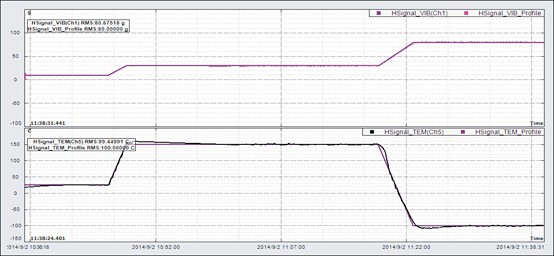

Comprehensive Test Curve

Typical Application

Technical Parameters Table 1

| RS Highly Accelerated Life Testing and Highly Accelerated Stress Screening | |||||

| Model | HH-500-30 | HH-700-50 | HH-900-150 | HH-1200-200 | |

| Temperature Range | -100°C~+200°C | -100°C~+200°C | -100°C~+200°C | -100°C~+200°C | |

| Temperature Ramp Rate | 60°C/min | 60°C/min | 60°C/min | 60°C/min | |

| Vibration Level | 70Grms | 75Grms | 80Grms | 75Grms | |

| Frequency Range | 10Hz-10000Hz | ||||

| Table Size | 500mm*500mm | 700mm*700mm | 900mm*900mm | 1200mm*1200mm | |

| Payload | 30kg | 50kg | 150kg | 200kg | |

| Workspace Dimensions | W | 700 | 1140 | 1140 | 1400 |

| D | 700 | 1140 | 1140 | 1400 | |

| H | 500 | 900 | 900 | 1400 | |

| Cooling Method | Liquid Nitrogen | ||||

| Liquid Nitrogen Requirements | 0.2-0.4Mpa | ||||

| Power Supply | 3/PE AC380V ±10% 50Hz | ||||

| Controller | HC-3000 | ||||

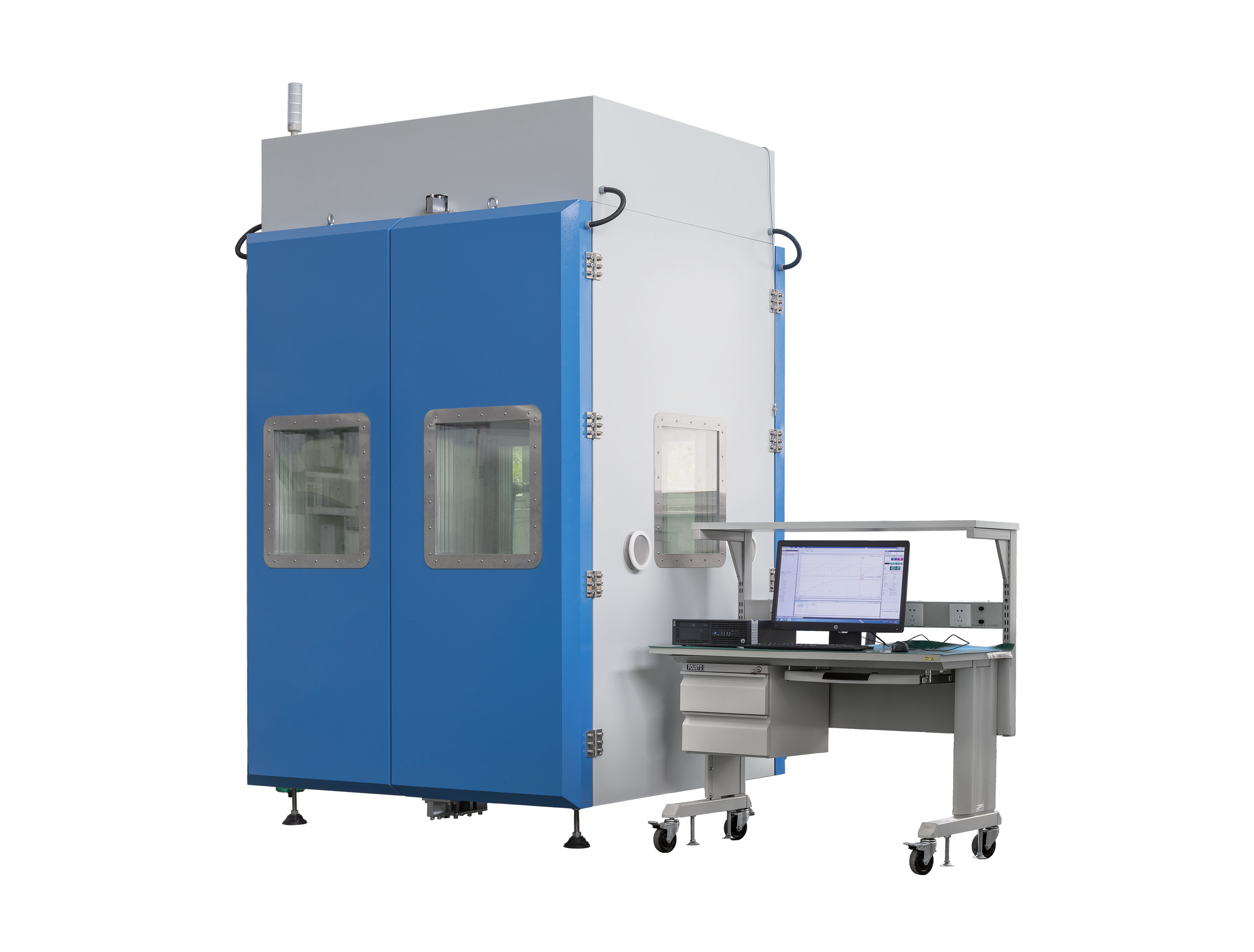

Electro-Dynamic Highly Accelerated Life Testing and Highly Accelerated Stress Screening

ED Highly Accelerated Life Testing and Highly Accelerated Stress Screening is made of ED shaker, rapid temperature chambers, integrated vibration and temperature controller.

The test frequency of ED HALT & HASS is less than 3000Hz. ED HALT & HASS can do common vibration tests with complex spectral types, wider applicability, and users can set the test types and vibration levels.

- ED HALT & HASS can provide the test methods of vibration synchronization and cycling Temperature synchronization,

- Cycling and shock,

- Integrated vibration and temperature and so on. The vibration types are sine, random, shock and so on.

Technical Parameters Table 2

| ED Highly Accelerated Life Testing and Highly Accelerated Stress Screening | ||||

| Model | HHED-600 | HHED-1200 | HHED-2200 | |

| Temperature Range | -100°C~+200°C | -100°C~+200°C | -100°C~+200℃ | |

| Temperature Ramp Rate | 60°C/min | 60°C/min | 60°C/min | |

| Vibration Level | 150Grms | |||

| Frequency Range | 5-3000Hz | |||

| Workspace Dimensions | W | 800 | 1100 | 1400 |

| D | 800 | 1100 | 1400 | |

| H | 950 | 1000 | 1400 | |

| Shaker Matching Table Size | Vertical Shaker | 600 | 800 | 1200 |

| Cooling Method | Liquid Nitrogen | |||

| Liquid Nitrogen | 0.2-0.4Mpa | |||

| Power Supply | 3/PE AC380V ±10% 50Hz | |||

| Controller | CEC-3000 | |||